Water leaps from leaf-like nanoscale pattern; desalination and power plants could benefit

By applying a nanoscale pattern that resembles a bed of tiny, pointed leaves and special coating, researchers at the Massachusetts Institute of Technology have managed to increase the efficiency of water condensing plates by nearly a third. Water droplets are so repelled by the combination that they appear to jump off the plates.

Though the hydrophobic, or water-repellant, coating is common, applying the new pattern could increase the efficiency of industrial plants relying on condensation for their operations as well as play a role in increasing the efficiency of the overall energy grid.

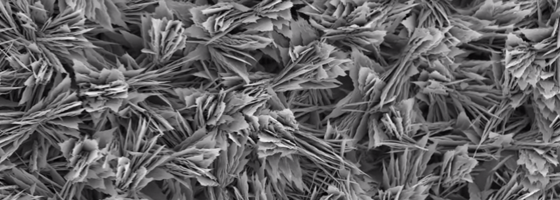

Jumping-droplet superhydrophobic condensation shown on a nanostructured CuO tube. (Credit: MIT)

Industrial applications for it are wide, ranging from uses in power generation to desalination plants, which are likely to become more common as world water resources become more polluted or scarce. It could also be applied to practices that harvest water from the atmosphere.

Condensation is a key component in making distilled water, which is used to improve the efficiency of steam engines and water boilers. In many power plants, water vapor is condensed and used for cooling. Desert areas could benefit from the new pattern, as some rely on water condensation to collect drinking water.

“Clean water resources have a high chance of decreasing over the next 50 years, both due to higher population and contamination,” said Nenad Miljkovic, a doctoral student at MIT and co-author of the research published in the journal Nano Letters. “This makes desalination an alternative option.”

Miljkovic says water condensation is widely used for temperature and humidity control.

“Condensation is also used for industrial and commercial buildings in controlling temperature and humidity,” said Miljkovic. “It’s also been used recently to take water vapor from the atmosphere and collect it as fresh water.”

As opposed to the current surfaces of condensing plates, the new one makes it possible to remove the water droplets more quickly by making them cool faster. Less cooling time means water condenses faster, which makes applications relying on it more efficient.

The increased efficiency depends in part on findings that indicated the importance of water droplet shape in making the plates cool quicker. The MIT team developed the leaf-like pattern that favored a better shape from those results. The pattern is applied directly to the copper condensing plates via a chemical reaction and then covered with a hydrophobic coating.

By making the plates more hydrophobic, the researchers estimate efficiency in cooling and condensation is increased by 30 percent.

“The coating is very inexpensive,” said Miljkovic. “The major expense is the copper, which is one of the most common heat transfer metals used in industry. A 30 percent heat transfer enhancement could mean using smaller heat exchangers, which would be a considerable savings.”

Applying the technology on a broader level could even yield more efficiency in supplying electricity.

“Using it for humidity control or harvesting water from the atmosphere would offset a lot of consumption within the energy grid,” said Miljkovic. “Especially considering the large size of industrial condensers and their copper material.”

Top image: Water condensates more quickly on surfaces with this leaf-like nanoscale pattern developed at MIT condensation (Credit: MIT)

0 comments