Scarce electricity and funds prompt low-cost, low-power turbidimeters

Unreliable electricity supplies in remote areas of Honduras have led some villages there to adopt novel gravity-powered drinking water treatment plants. But funds for monitoring are often just as elusive.

A team of graduate and and undergraduate students from Johns Hopkins University and Cornell University are looking to change that by developing low-cost turbidimeters that don’t depend on a consistent electricity supply and which can communicate wirelessly with the internet.

Chris Kelley, a doctoral student in environmental engineering at Johns Hopkins, was working on projects related to data analysis and communications for rural water monitoring programs. He sought real-world applications of that work, which led him to AguaClara, a Cornell University Program that has developed gravity-powered water treatment plant designs. Several plants based on these designs have been built, and now serve clean water to more than 30,000 people across Honduras.

Kelley visited Honduras in 2012 to see the plants first-hand.

“AguaClara has done a pretty amazing job of designing reliable, low-cost water treatment technologies,” Kelley said.

He also observed plant technicians monitoring turbidity with handheld meters and writing down records on paper in an area with no functioning postal system. A light went off for Kelley that they needed a better way to communicate this data. A collaboration with Monroe Weber-Shirk and Alex Krolick of AguaClara led to the development of a text-message based system that allows plan operators to send any kind of water data over the phone to a web server and have that data broadcast to the world. The results can be viewed at map.wash4all.org.

That improved the data communication, but it highlighted a bigger issue: these particular plants are well-equipped for water treatment monitoring in part through university and NGO connections. For plants with even fewer resources, monitoring can be hampered by equipment costs. Devices to monitor turbidity, in particular, are both crucial and expensive.

“So we’re trying to design devices appropriate for turbidity monitoring in areas of very limited electricity and low economic resources,” Kelley said.

After some shopping around, Kelley said he and his collaborators couldn’t find a turbidimeter for less than $500, and most options were between $700 and $1,000. Their goal was to cut that by an order of magnitude, which seems to be close at hand.

“We originally aimed for $100 because that seemed ambitious,” he said. “We think we can now, even including labor costs, deliver a product for $50 that can monitor turbidity almost as well as the more expensive commercial models.”

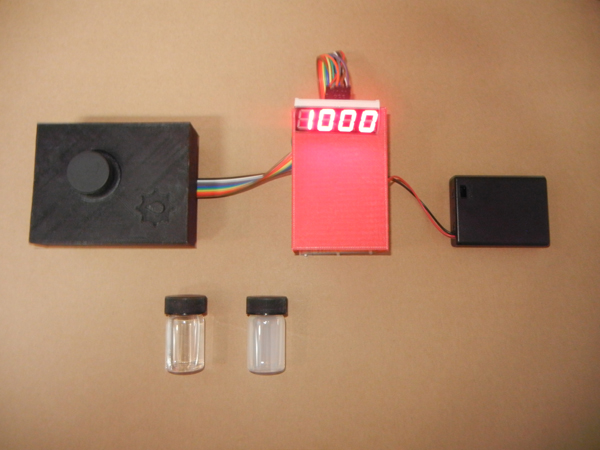

The turbidimeter’s sensor and light source (left), circuit board and display panel (center), and battery case (right) will be combined into one case in the final model.

Kelley and Krolick built an early model of their handheld turbidimeter using a laser, a photodiode, and an Arduino microcontroller. Data were communicated via Bluetooth to an Android phone that could display the measurements to the operator and broadcast them to the Web. After they were encouraged to develop an even less expensive model, they recruited more students, swapped the photodiode for a light-to-frequency sensor, and scrapped the wireless communications for a four-digit display panel like those on old alarm clocks. This model can measure down to 0.5 NTU, below the international drinking water guideline of 1.0 NTU, but well above the threshold of commercial meters which can measure down to 0.02 NTU.

The team was recently awarded a grant from the U.S. Environmental Protection Agency for an in-line version of the turbidimeter that broadcasts continuous measurements via an integrated cellular modem. Technicians at the AguaClara plants in Honduras now are generally sending data twice a day, which is good enough to give a general indication of the plant’s long-term operations. But an affordable, battery-powered turbidimeter that can transmit measurements frequently and automatically would allow water authorities to better monitor how plants are responding to individual rainstorms.

“If you always had a trained operator in every plant every hour, then inline monitoring would be less important”, Kelley said. “But that’s not the case. It’s often too expensive, and inline turbidity meters can run thousands of dollars.We hope this will provide a way of getting automated supervision, which helps you affordably extend your monitoring reach in remote and resource-poor settings.”

0 comments