Wave Sensors Integration with NexSens Buoys: A Cutting-Edge Solution for Wave Measurment

Real-time wave data supports accurate weather prediction, safe and efficient maritime operations, and provides valuable safety and operating condition information for recreation and commercial fishing.

Understanding wave dynamics also helps with the design of protective coastal structures like seawalls, breakwaters, and jetties. It also supports better prediction of their impact on sediment transport and coastal geomorphology.

Wave data is a key factor in qualifying and designing offshore wind farms and harnessing kinetic energy for electrical generation. It helps with the understanding of ocean-atmosphere interactions and contributes to studies of sea-level rise and climate change impacts.

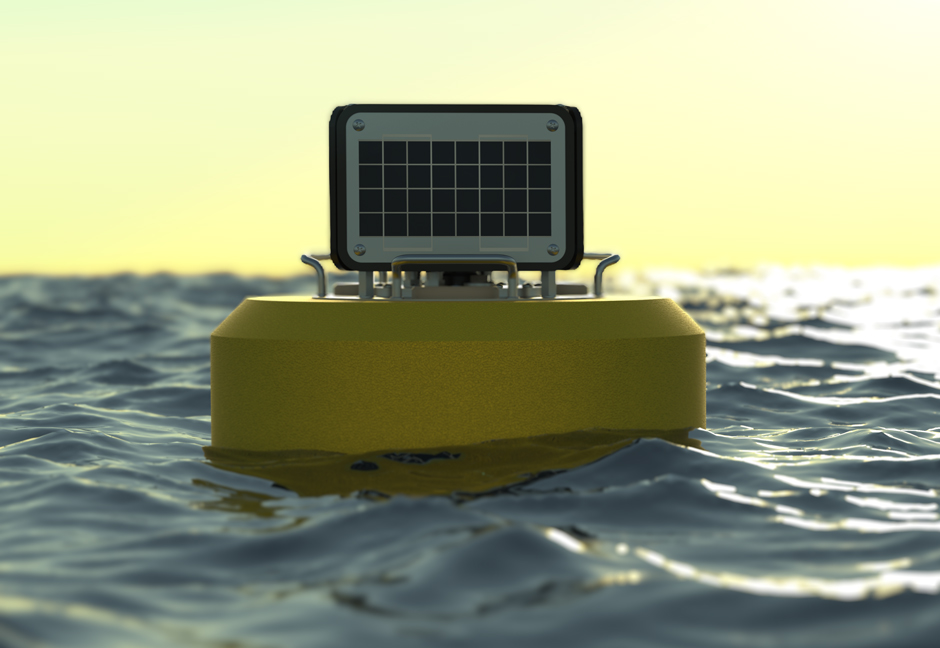

A NexSens CB-75-SVS Wave Buoy. (Credit: Emma Jones / Fondriest Environmental)

Revolutionizing Marine Monitoring

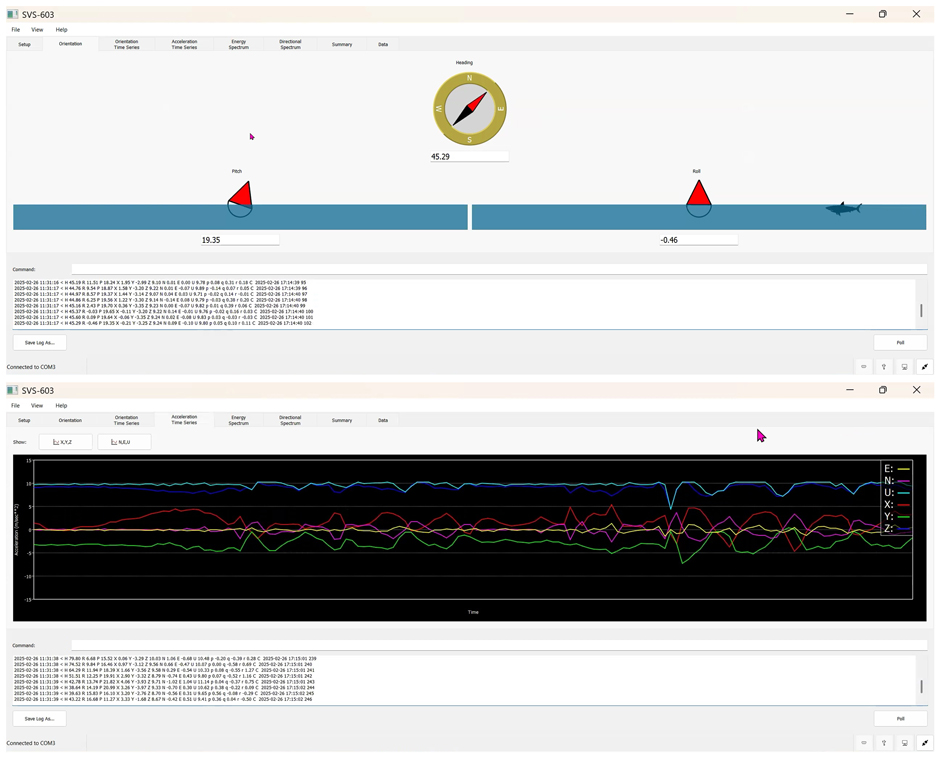

Wave sensors like the SeaView SVS-603HR are revolutionary for marine monitoring, providing accurate measurements of wave height, period, and direction. These advanced sensors detect motion and orientation of floating platforms–such as NexSens buoys–transforming raw data into actionable insights with the help of sophisticated algorithms.

Unlike seafloor-deployed Acoustic Wave and Current Profilers (AWAC), the buoy-based SeaView sensor calculates wave statistics directly and operates with significantly lower power consumption, making it ideal for long-term, real-time monitoring.

Designed for surface monitoring rather than bottom-mounting, these sensors can function on moored and drifting buoys, offering enhanced deployment flexibility.

Timothy Crandle, President at SeaView, explains that in comparison to previous generation wave measurement systems and their “power-hungry hardware,” the SVS-603HR, which uses an inertial measuring unit (IMU) and a microcontroller, uses a fraction of the power and physical footprint.

“The low power consumption and minimal maintenance offered by the SVS-603HR make it the ideal tool for deepwater extended duration deployments or smaller platforms where available power and payload capacity are limited,” says Crandle.

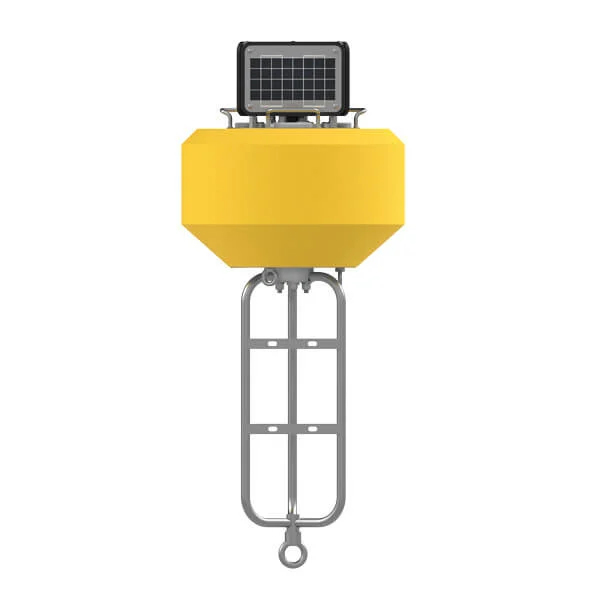

When paired with NexSens buoys, this system is small and compact enough for solo deployments. It is ready to handle harsh environments, combining modularity and durability.

“We’ve been developing a massive library of deployment data over the past seven years on just about every buoy or vehicle you can imagine,” states Crandle. “This gives us an invaluable foundation of buoy behavior for nearly any platform we encounter.”

And part of the ongoing development and qualification of the sensor includes direct comparison with several previously standard wave measurement systems, including both buoy-mounted sensors and bottom-mounted systems like AWACs.

How to Measure Waves with MEMS

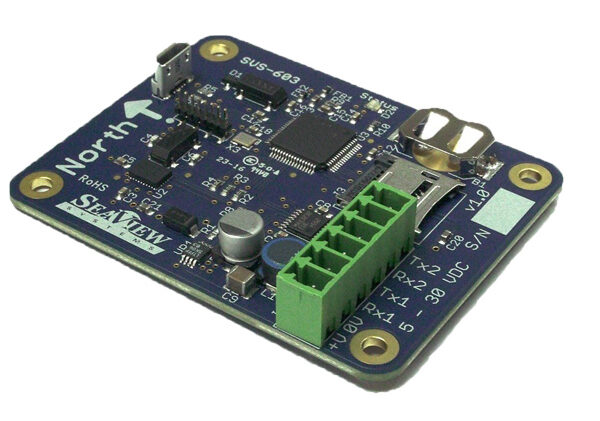

The SeaView sensor relies on a microelectromechanical systems (MEMS) inertial measurement unit IMU to monitor platform motion, orientation, and angular velocities in all three axes.

The accelerometer detects vertical and horizontal movement, indicating the orbital motion of the buoy or vehicle platform, which is essential for measuring wave height, wave period, and direction. The sensor also includes the capability to apply an on-board Response Amplitude Operator (RAO) that can correct for specific characteristics of the deployment platform.

The sensor’s gyroscope and magnetometer detect the buoy’s tilt, helping correct the effects of non-ideal buoy motion by accounting for pitch, roll, and yaw as well as allowing for flexible sensor placement.

Using the data from these sensors, advanced signal processing algorithms are applied to separate out the different forces acting on the buoy.

A Kalman Filter maintains the accuracy of each of the readings from the accelerometer, gyroscope, and magnetometer, as well as a Fast Fourier Transform, which helps isolate the wave-induced motion from noise or other sources of motion that are not the result of waves.

Exceptional Accuracy in Challenging Conditions

The SeaView sensor stands out among buoy-based sensors for its exceptional accuracy in wave data collection, making it ideal for research and engineering applications that demand precise wave spectra with fine resolution.

Its high sensitivity and advanced proprietary algorithms enable it to capture rapid and extreme wave fluctuations with remarkable detail–it can measure wave heights with a resolution of 0.1 cm.

With millisecond period resolution and up to 8 Hz output statistics, the sensor provides detailed directional spectra, enabling the identification of multiple overlapping wave systems, such as swell and wind waves.

See the table for comparison metrics:

| Feature | Seaview SVS-603HR | Typical |

| Wave Height Accuracy | < ±0.1 cm | < ±5 cm |

| Wave Period Accuracy | ±20 ms | Not Disclosed |

| Wave Direction Accuracy | < ±1º | Not Disclosed |

| Sampling Rate | up to 8 Hz | 2.5 Hz |

| Multiple Waves | Accurately resolves overlapping wave fields (swell + wind waves) | May struggle to resolve two simultaneous wave directions precisely. |

| Field Trials Comparison | Nortek AWAC – R² = 0.9913 Teledyne ADCP – R² = 0.95778 | Not Disclosed |

| Data Online | NexSens WQDataLive | Through the integrated platform |

| Platform Used | NexSens open platform with standard protocols | Closed platform |

| Cost | $8,000 | $5,000 |

How SeaView Sensors Work

SeaView’s technological lead comes not just from their unique approach of using MEMS sensors but also through data processing using their proprietary algorithms. This includes the Mean Noise Filter (MNF), which eliminates spurious data and reduces the effects of non-wave motion, such as buoy vibrations or sensor noise. These filters work by distinguishing between wave-induced motion and platform movement.

The SVS-603HR’s built-in motion compensation algorithms, powered by onboard accelerometers and gyroscopes, are specifically designed to correct for platform motion, making the sensor highly adaptable to a variety of hull designs and deployment scenarios.

Seaview SVS-603HR sensor board. (Credit: Emma Jones / Fondriest Environmental)

Tested Capabilities

The Seaview SVS-603HR has proved itself in field tests, comparisons against both radar systems and acoustic doppler systems. Moreover, each sensor is individually verified.

Crandle explains, “We’ve got a diverse battery of tests that we put the sensor through when we’re doing a release qualification, and we do a subset of that test every time we ship a sensor out. We run it through various tests, qualify its accuracy, confirm its calibration, and so on before it gets shipped to customers.”

Mara Isenstein, Project Engineer at Seaview, demonstrates moving a SeaView sensor and the real-time visualization of the tracking updating at 4Hz wave statistics. (Credit: Seaview)

Integration with NexSens Buoys

All of the NexSens data buoys offer seamless integration with the Seaview SVS-603HR via the X3 data logger, and the NexSens CB-75-SVS Wave Buoy offers a premade system.

By connecting to the NexSens buoy, clients can benefit from:

- Real-Time data: NexSens systems support cellular, satellite, or radio telemetry, allowing wave data to be transmitted instantly. This is critical for applications like storm surge monitoring or real-time navigation alerts. Ready to view and access via WQDataLive– NexSens’ provided data portal.

- Modularity and versatility: The modular design of NexSens buoys enables the addition of other sensors, creating a comprehensive monitoring platform that can be uniquely tailored to a client’s requirements. From open oceans to estuaries, NexSens buoys can be customized to meet specific needs, including mooring configurations and power systems.

- Ease of deployment: The compact and robust design of NexSens buoys simplifies installation and maintenance. The power system aboard can easily support the requirements of the SeaView wave sensor.

- Cost-effective: NexSens buoys are particularly cost-effective for smaller research teams or localized deployments. The majority of the cost of research projects is maintaining the equipment, but with light buoys and integrated sensors, this is drastically reduced, for example, in the NOAA Chesapeake Bay Program.

The NexSens CB-75-SVS Wave Buoy. (Credit: Emma Jones / Fondriest Environmental)

Applications

The integration of SeaView sensors within NexSens buoys has wide-ranging applications. For example, weather and coastal management, and research into climate change mitigation in environments as contrasting as the North Sea and the Indian Ocean.

This SeaView sensor has been tried and tested. Crandle highlights, “The maturity of the SeaView sensor is important, it has been proven by multiple coastal agencies such as NOAA, who use this sensor across multiple buoy networks.”

Large industrial enterprises such as wind farms and fish farms also rely on SeaView sensors for “qualification projects for site selection,” and they are at the cutting edge of marine monitoring technology. “The sensors are leading the charge into small vehicles that have wave sensors on them,” said Crandle.

The Future

The future of marine monitoring is in technology that is evolving to meet customers’ needs and pushing the limits of technological progress.

As the underlying sensors are increasing in accuracy, the utility of these measurements has increased. Crandle explains, “People are seeing things that wouldn’t have been practical before, like looking at more directional spectra. But now we are able to produce refined measurements.”

Wave sensors like the SeaView SVS-603HR are redefining the landscape of marine monitoring. Their unique capabilities, when combined with the modular and robust design of NexSens buoys, offer a comprehensive solution that surpasses many other systems in terms of adaptability, precision, and cost-efficiency.

Whether for weather, shipping, maritime safety, scientific research, or coastal management, this integration represents the cutting edge of ocean monitoring technology.

0 comments