Revolutionizing Conventional Solar Water Evaporation With Hydrogels

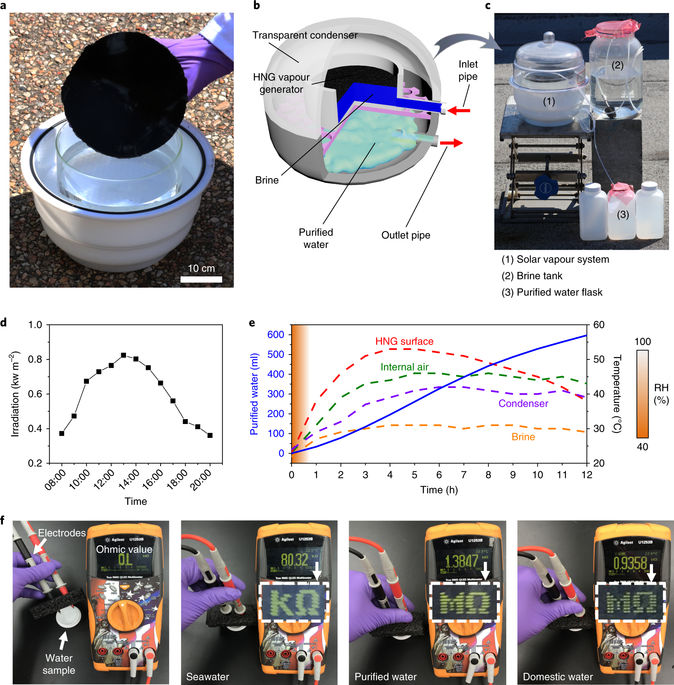

Outdoor solar water purification using HNGs in natural sunlight. (Credit: Zhao, et al.)

Saline water—classified as having more than 1,000 ppm of dissolved salts—can be made into freshwater through desalination. The process is typically fueled by the sun, or by some other power source heating the water; after the heat energy turns the saline water into steam, one captures the steam, and then distills it back into water as it cools and condenses. On a small scale, such as that of an individual-sized still, it’s a simple, rain-inspired process, albeit a slow one.

Large-scale methods are available, but to be practical, these technological processes have to remain on a massive scale, and any way you slice it, they are energy-intensive, costly, and require large-scale facilities. The challenge, then, is to come up with new technologies that are less expensive and less energy-intensive.

Distillation not only removes salt, but also other contaminants, so it’s been a traditional standby treatment process. The challenge to improve upon it is growing more urgent as the Earth’s population booms and freshwater resources dwindle thanks to pollution and drought. Salinity is a problem in at least 30 percent of the world’s irrigated regions, and remediation is very expensive, creating additional need for low-cost desalination.

A research team from the Cockrell School of Engineering at the University of Texas at Austin has been working on this issue. Led by associate professor of materials science and mechanical engineering Guihua Yu, the team has come up with a breakthrough in desalination technology, thanks to combined gel-polymer hybrid materials—hydrogels. Dr. Yu corresponded with EM about the research.

Framing the problem

Obviously, there are a number of weaknesses in the existing “state of the art” for desalination. The team took a systematic approach to dealing with each weakness in turn.

“Thermal-based water purification is the mainstream industrial tech, such as multi-effect distillation (MED), multi-stage flash distillation (MSF) and mechanical vapor compression (MVC), which separates water and impurities through water vaporization to produce high purity output water,” explains Yu. “Solar water purification is an emerging promising alternative, using solar energy to heat water for evaporation. However, due to the large phase change enthalpy (i.e. energy required for water vaporization), thermal water purification is typically an energy-intensive process.”

Therefore, to provide enough energy for the water evaporation step of the process, most industrial solar water purification systems utilize costly and complex optical concentrators (OCs). These focus sunlight to heat the water. However, such optical concentration leads to higher construction and maintenance costs.

“Our innovation provides the possibility of ending the dependence on these costly OCs and installations,” details Yu. “More importantly, in terms of a more fundamental understanding of solar water evaporation, our research offers a new perspective: that the interaction between functional material and water plays a significant role, whereupon material science and engineering could be helpful to improve the performance of solar desalination.”

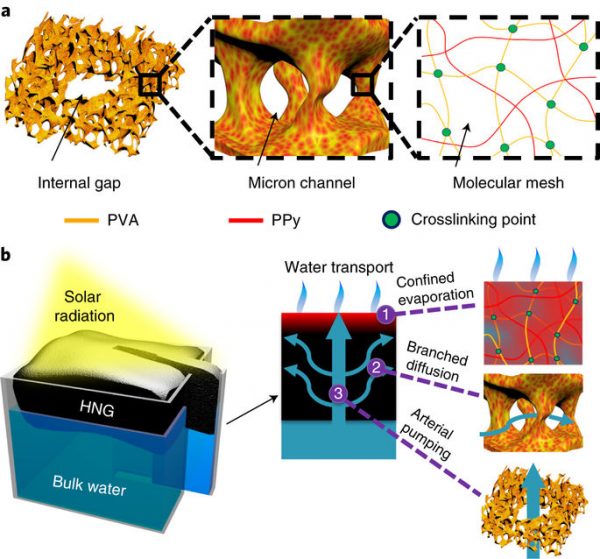

Schematic of highly efficient solar vapour generation based on tailored water transport in HNGs. (Credit: Zhao, et al.)

Hydrogels are known for their high water absorbency, because they both attract water and then trap it. This is an important part of the team’s new technology.

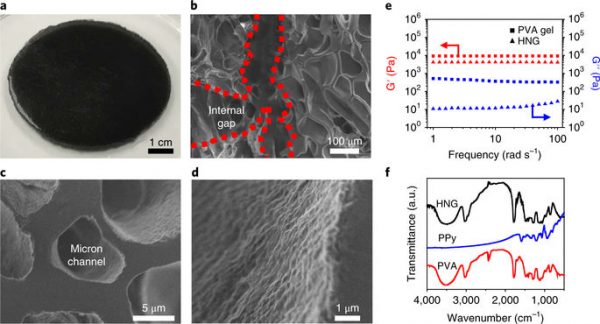

“Hydrogels have two parts: ‘hydro’ and ‘gel,’ where ‘hydro’ refers to contained water and ‘gel’ represents its skeleton,” Yu describes. “These polymers are fibers, polymer chains, at the molecular scale. When they react with crosslinkers, fibers are interconnected with each other to form a three-dimensional polymer network. The hydrophilic functional groups on the polymers are able to act as traps to hold water molecules, and many of these together form molecular meshes that play the role of chambers to store water molecules.”

What sets this particular hydrogel apart, however, is its solar abilities.

“Regarding this specific gel in this technology, we integrated a light absorbing polymer (polypyrrole, PPy) with a conventional water absorbing gel (polyvinyl alcohol (PVA)), so that the newly-obtained gel can be efficiently heated by sunlight, evaporating the absorbed water,” adds Yu.

This overall design and set of qualities means more evaporation with a much lower energy price tag.

“In solar water purification, the separation of contaminates and water relies on the evaporation process,” remarks Yu. “When the water in the hydrogel vaporizes, the impurities such as salt will be left in the hydrogel. The vapor can be condensed elsewhere to obtain the purified water. The most significant point of our research is that our gel can facilitate this evaporation process, and work effectively and robustly for a long time.”

In fact, according to Yu, the solar desalination process achieved in tests significantly reduced the salinity of seawater—by about 3 to 4 orders of magnitude.

Rewriting the desalination playbook

In a press release, Yu indicated that the team has “essentially rewritten the entire approach to conventional solar water evaporation.” Given that the team’s hydrogel-based solar vapor generator was able to achieve drinking water standards with samples from the Dead Sea using ambient solar energy for power, this seems accurate. Outdoor testing produced as much as 25 liters of drinking water for every square meter—and it can remove more than just salt.

“The basic needs [for disaster areas and home use] are similar: purify water using solar energy without an external power supply,” clarifies Yu. “The difference is the possible impurities. For household use, the impurities might be organics such as detergent or oil contamination. For emergency use during a disaster, the major impurities could be mud, microorganisms, and other insoluble pollutants.”

Characterization of the HNGs. (Credit: Zhao, et al.)

This unique hydrogel is able to vaporize more water using less energy because its polymer network can break even the strong interactions among water molecules in liquid water. Another important innovation in this work is the ability to avoid reinventing the wheel despite this technological advance.

“While our material enables solar desalination without a distillation system, it is potentially compatible with current industrial distillation systems, which can significantly enhance energy utilization efficiency through optimized chemical engineering design,” states Yu. “In other words, our hydrogel can be used not only to fabricate ‘portable purifiers’ for domestic or emergency uses, but also to replace the solar evaporator materials in conventional industrial distillation systems in the near future.”

In terms of what’s coming next for the team, scalability tests are in the near future.

“Regarding scalability, we are working in two parallel directions,” remarks Yu. “One is the scaling of materials fabrication; we already made samples of about 10 inches in area, and now we’re working on even larger sizes. The other is to fabricate practical, portable solar water purification devices based on our gel to move the laboratory achievement to commercialization stage. Moreover, we will collaborate with other experts to evaluate our gel in industrial solar desalination systems.”

Yu believes that ultimately these materials and the technology may be in use at an industrial scale, deployed by municipalities, after they’re first put to work in smaller devices used by individual households.

“The design of materials, especially materials for solar evaporators, benefits the further development of solar-powered water purification,” adds Yu. “Low-cost, scalable, hydrogel-based materials hold promise for system-level applications in industrial water treatment.”

0 comments