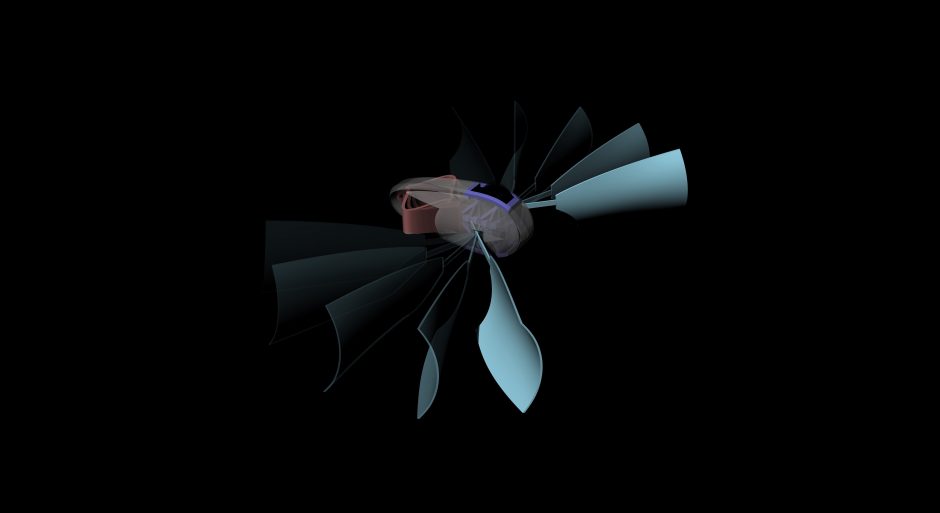

Soft, 3D-Printable Robot Exploits Temperature Changes in Water to Self-Propel

Visualization of a simple mini-submarine with two paddles. (Credit: ETH Zurich / Tim Chen, https://www.eurekalert.org/multimedia/pub/172382.php?from=396164.)

Imagine fleets of compact, self-propelling robots quietly making their way through the world’s oceans, surveilling marine life and monitoring conditions, each one moving without a power supply or even an engine. It may sound like science fiction, but thanks to a team of researchers from ETH Zurich and Caltech led by Professor Kristina Shea, this new concept for self-propelling, swimming robots that exploit in-water temperature fluctuations to move, has now undergone a successful proof-of-concept study.

“We had already developed 4D printed deployable structures that use the combination of shape memory polymer strips and tunable, bi-stable joints to reconfigure themselves from flat structures into different forms,” explains Professor Shea. “Our colleagues at Caltech were interested in how to apply this to create an untethered, propulsion device, i.e., a swimming submarine or robot.”

Snapping back

In the study, the team developed and fabricated a 7.5-centimeter mini-submarine using a multi-material 3D printer. The little sub is equipped with two shape memory polymer strips it uses as paddles. The “paddles” expand in warm water and then snap, contracting like muscles and triggering a paddle stroke. The robot’s material and geometry precisely control the force, directional motion, and timing of the paddle strokes.

“Imitating the motion of rowing boats, frogs or water striders, the swimming robot propels itself forward by driving its oars back,” details Professor Shea. “Instead of using an electric motor connected to a power source, the oars are driven by a bistable element, similar to a ‘snap bracelet,’ that is triggered by a shape memory polymer (SMP) muscle.”

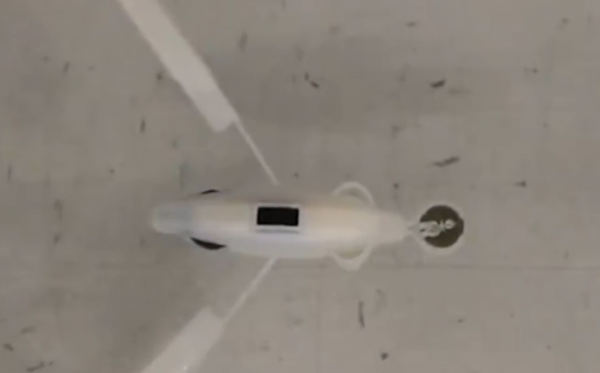

Right now, the team is working on more complex movements for the robots. To start with, each actuator could execute just one paddle stroke, needing to be reprogrammed afterward. However, when multiple actuators with varied geometry in the polymer “muscles” work together, more involved movement is possible. Watch a video of a sub paddle forward, drop a coin, and paddle backward here.

Scientists can define where the paddle stroke is triggered, and different temperatures can trigger different responses from strips of varying thicknesses.

Screenshot, the sub paddling forward to drop its coin cargo. (Credit: ETH Zurich, https://www.youtube.com/watch?v=ulF1xEfCHBs.)

“A shape memory polymer is a type of plastic that becomes compliant when heated,” Professor Shea describes. “Most thermosetting polymers (i.e., irreversibly cured plastic from a liquid resin via heat or light) exhibit this behavior.”

Users can “program” the SMP to morph from its permanent shape into a second shape when it is heated. When the SMP cools down, this new shape becomes stable, yet the material does not lose its “memory” of its permanent shape—reminiscent of a muscle memory. When the material is reheated, its permanent shape returns.

“In doing so, it delivers a force to the bistable element,” states Professor Shea. “By changing the chemical composition of the resin, the temperature at which the transition occurs can be tuned. Mechanical bistability refers to a system that when enough force is applied, ‘snaps’ to a second state. It’s the ‘snapping’ behavior that drives the oars.”

A soft, 3D-printed future

The ability to fabricate these robots using a 3D printer will mean easier, quicker deployment, and more customizable results.

“This robot can be fully 3D printed using a multi-material 3D printing process,” remarks Professor Shea. “This means that those that want to deploy this robot can tune it to their purposes and fully 3D print their design. No other parts, such as motors, batteries, controllers, et cetera, are needed. It is also designed modularly, and so replacement parts can be easily printed.”

In the future, the team may be working on polymers that respond to other triggers such as salinity or acidity. This research has yet to begin so Professor Shea cannot comment on it, beyond adding, “We haven’t started on this, yet so I am hesitant to say anything. The goal of 4D printed designs is that they are activated by environmental triggers. We have shown temperature change as the trigger, but it could be other aspects of the water, e.g., salinity or acidity.”

Screenshot, a scientist holds one of the contracting actuators. (Credit: ETH Zurich, https://www.youtube.com/watch?v=ulF1xEfCHBs.)

A vehicle that doesn’t need a power source would be revolutionary for exploring the deep sea, in part because the need to go back to a ship for more power is such a limiting factor. How far off the deployment of small undersea “drones” of this kind, still remains to be seen.

“We have shown here a new principle for creating such a ‘drone’; further research is necessary to enable continuous motion of the robot without the need to ‘re-program’ the shape memory polymer strip,” comments Professor Shea.

The team also foresees other uses for this kind of device.

“In addition to exploration in the sea, we see potential also for environmental monitoring (triggered by request) by adding sensors for gathering data to the ‘drone,’” remarks Professor Shea. “The main takeaway from our work is that we have developed a new and promising means of propulsion that is fully 3D printed, tunable, and works without an external power source.”

Top image: Visualization of a simple mini-submarine with two paddles. (Credit: ETH Zurich / Tim Chen, https://www.eurekalert.org/multimedia/pub/172382.php?from=396164.)

0 comments